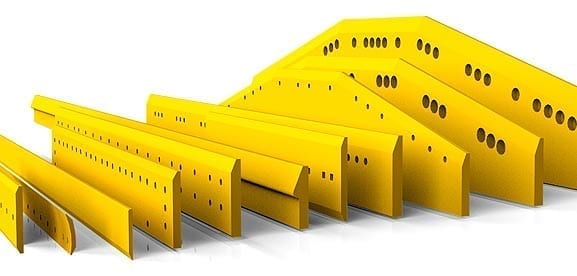

BYG offers a wide range of blades and endbits that cover all models and makes in the market. Designed to protect and prolong the life of the components of your machinery. BYG blades are manufactured in different alloys depending on the strength, penetration and resistance to wear needed.

Cutting edges and end bits

BYG Classic blades are manufactured in different qualities and measures according to the requirements of the work to be done. BYG produces high quality blades in carbon alloys that reach 250 Hb. BYG also manufactures blades from rolled steel sections (straight, single bevel, double bevel, half arrow, armored bars, etc…) and from steel plates of the best brands, such as HARDOX, WELDOX, HITUf and others. BYG is an authorized HARDOX manufacturer.

BYG also has a complete range of direct replacement endbits for all types of machinery: bulldozer, loader, scraper, etc.

COMPLETE INVENTORY OF BLADES

BYG offers blades of different sections to facilitate installation, maintenance, handling and storage. BYG blades are manufactured from rolled steel and hardened for greater resistance to wear. BYG produces two types of blades: STANDARD BLADES for general use and CAST BLADES for high abrasion or impact applications.

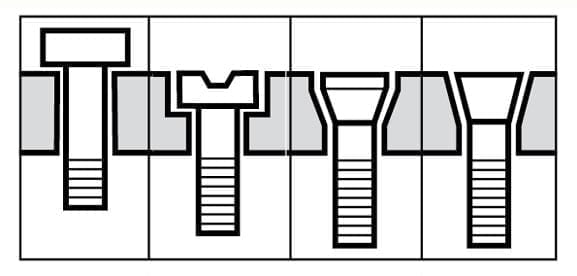

There are also 6 types of endbits available. The ranges includes UT (Utility endbits) for low abrasive material up to Tungsten overlayed endbits for extreme conditions.

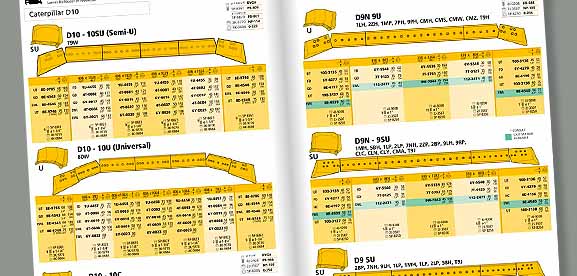

TECHNICAL CATALOG AND ONLINE SHOPPING

BYG has a comprehensive stock of blade partnumbers available at the facilities in Barcelona.

BYG is a specialist in the manufacture and supply of blades for the construction, public works and mining sectors. BYG manufactures blades compatible to all the major brands in the sector:

- Caterpillar

- Esco

- Komatsu

- Volvo and more

The premium brand of wear material FUTURA also has its own range of specialized blades. The FUTURA premium blades are characterized by their high resistance to abrasion and are indicated for low impact and high abrasion applications. All FUTURA blades are bolt-on edges, thus need to be assembled with bolts. The FUTURA 550 blades offer up to 60% more wear life compared to 500 brinell boron blades from other brands.

BYG specialises in blade, cutting edge, endbit and segment manufacturing. The production facilities of BYG in Barcelona offer different qualities of steel:

- 250 HB

- 450 HB

- 550 HB

BYG will also manufacture any type of cutting edge according to your specifications. BYG also has a complete range of compatible endbits for all types of machinery: bulldozer, loader, scraper, motorgrader, etc.

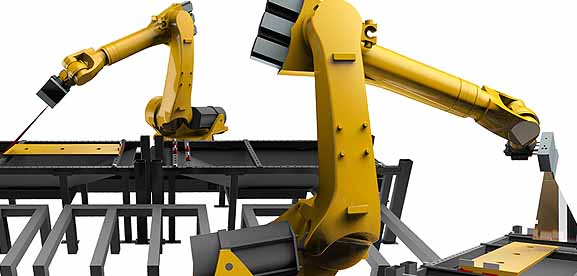

CUTTING EDGE and endbits manufactured on demand

BYG owns the most modern technology and specialized robots in the manufacture of blades for public works machinery and mining in its facilities in Barcelona. BYG offers the possibility of producing blades on demand from profiles from 4mm to 160mm thick. BYG also offers a service of oxycut to any shape an drilling of blades on request.

Bimetallic plates consist of a layer of chromium carbide welded on a base plate of malleable steel. BYG bimetallic plates are assembled in a welding machine of own design with exclusive technique.

BYG bimetallic steel plates offer excellent performance and abrasion resistance. Bimetallic plates are the ideal solution for any of these applications:

- Bucket protection

- Reinforcement of bulldozer blades

- Bulldozer and loader reinforced segments

- Side and bottom bucket protectors

ADVANTAGES OF BIMETALLIC PLATES

Bimetallic plates protect the components of your machinery against wear in critical areas. Compared with standard blades, bimetallic parts can last up to 3-5 times longer in conditions of high abrasion / low to moderate impact. This represents a substantial saving in total operating costs.

BYG polyurethane blades are specially indicated for jobs that require flexibility or where the preservation of the integrity of the surface is important, as is the case of asphalt or concrete.

The most common applications for the BYG polyurethane blades are:

- Snow plows

- Transportation (Airports, highways, roads or ports)

- Loader machines

- Farm Equipment

- Industrial machinery (plaster, chemical, paper, recycling, sulfur)

polyurethane blades: advantages

These are some of the advantages of polyurethane blades:

- Polyurethane offers abrasion resistance with slow and uniform wear.

- BYG polyurethane blades are characterized by their excellent elasticity and flexibility.

- Polyurethane blades do not damage the road surface or horizontal signs

- Polyurethane blades reduce noise and vibrations

- Polyurethane is free of corrosion and oxidation

POLYURETHANE SNOWPLOW BLADES

BYG offers a complete range of standard polyurethane blades for snowplow machinery. BYG polyurethane blades are manufactured in these standard thicknesses (30mm, 40mm and 50mm) suitable for use in most snow plows. BYG specializes in the production of snow blades for the most important brands in the sector, such as:

- Schmidt

- Assaloni

- Giletta

- Fresia and more

COMPLETE RANGE OF POLYURETHANE BLADES

Polyurethane blades are used in many sectors of the industry thanks to their multiple applications:

- Snowplow machinery (Assaloni, Giletta, Fresia and more)

- Industrial machinery (handling of plaster, chemicals, paper, recycling, etc.)

- Transportation (maintenance of airports, highways, roads and ports)

- Agricultural (handled livestock, cereal, cotton, straw, olive …)

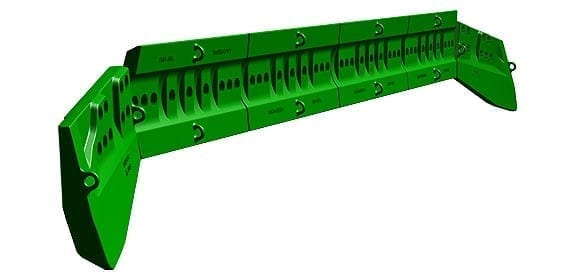

The picture shows a polyurethane blade supplied by BYG for use in a VOLVO brand LOADER for handling sulfur.

BYG offers blades of different sections to facilitate installation, maintenance, handling and storage. BYG blades are manufactured from rolled steel and hardened for greater resistance to wear. BYG produces two types of blades: STANDARD BLADES for general use and CAST BLADES for high abrasion or impact applications.

Cast endbits are notably reinforced in their perimeter and present a protruding rib to the tip providing greater resistance to breakage.

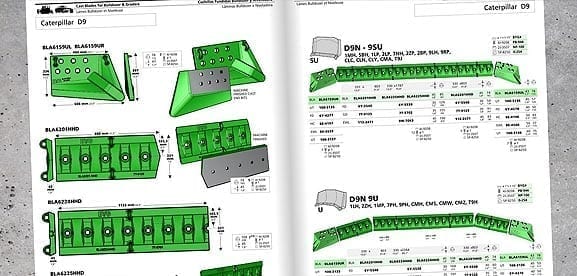

CAST BLADES CATALOG

BYG offers a complete range of cast blades to assemble complete equipment of both bulldozers and grader machines. The BYG cast blades are available for the following equipment:

- Bulldozers Caterpillar: D11, D10, D9 and D8

- Bullozer Komatsu: D375 and D475

- Niveladora Caterpillar: 14H, 14M, 16H,16M, 160H, 160M, 24H, 24M

ADVANTAGES OF THE CAST BLADES

BYG cast blades and endbits BYG are easily identified by the reinforced rib of the corners. Cast blades are remarkably reinforced around their perimeter providing greater resistance to breakage. The endbits carry one or more rings for handling. In addition these blades are machined in the back to facilitate placement on the original machinery.

Extended wear life

BYG blades can be replaced, alternated or rotated individually. That's why they are more economical, since each blade can be used to its maximum wear life.

Designed for maximum protection

The thickness in the area of the screw hole is the same as that of the blade for long life and greater protection of the screw head.

Complete thickness range

BYG blades and end bits are available in different thicknesses (form 4mm to 160mm) depending on the requirements of the machine and the work to be done.

Oxi-cut and drill on demand

BYG has a production plant that offers the possibility of manufacturing<br /> customized blades on demand.

Blade and segment expert

BYG has a complete inventory of blades organized by OEM part number and by measurement. If you need a specific blade, ask us.

Special cast blades available

For use in high abrasion and/or high impact. They are notable reinforced, providing greater resistance to breakage.